工业机器人在铸造行业的应用

Application of industrial robot in foundry industry

在铸造生产中,工业机器人除了能够代替人在高温、污染和危险环境中工作外,还可以提高工作效率,提高产品精度和质量,降低成本,减少浪费,并可获得灵活且持久高速的生产流程。

In casting production, industrial robots in addition to replace human work in high temperature, pollution and hazardous environment, but also can improve work efficiency, improve product precision and quality, reduce cost, reduce waste, and can achieve flexible and durable high-speed production process.

机器人将铸造工艺、铸造设备、工业机器人有机结合,不断研发铸造领域的项目应用,已覆盖压铸、重力铸造、低压铸造及砂型铸造等各个领域,主要涉及制芯、造型、 清理、机加工、检验、表面处理、转运及码垛等工序中。

The robot will be casting process, casting equipment, industrial robots combine continuous casting research projects in the field of application in various fields have been covered, die casting, gravity casting, low pressure casting and sand casting, mainly involving core making, molding, machining, inspection, cleaning, surface treatment, transport and palletizing process.

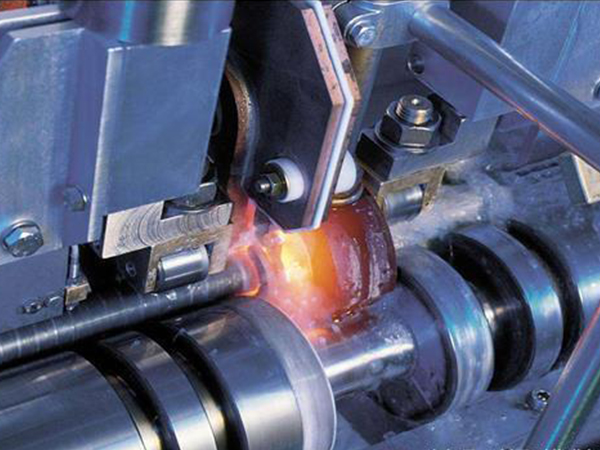

而铸造车间尤为突出,充斥着高温、粉尘、噪声等,工作环境极其恶劣。工业机器人可应用到重力铸造、低压铸造、高压铸造、旋压铸造,涵盖黑色金属和有色金属铸造不同铸造方式的车间,大幅度降低员工的劳动强度。

The foundry workshop is particularly prominent, full of high temperature, dust, noise, etc., the working environment is extremely harsh. Industrial robots can be applied to gravity casting, low pressure casting, high pressure casting, spinning casting, covering ferrous metal and non-ferrous metal casting different casting workshop, greatly reducing the labor intensity of employees.

工业机器人在铸造其他环节的应用

Application of industrial robot in casting other links

工业机器人因高度的柔性和精度,在油漆粉尘漫天飞舞的涂装车间、车间内不能连贯的两道工序之间、产品完成后的码垛、单机加工的上下件等铸造的诸多领域均可大显身手。比如在后端的机加工件上下料过程中,上下料机械手可以完全代替人工来操作,不仅速度快,而且稳定性高,特别是这种恶劣的环境下,企业一般很难招到合适的工人,而上下料机械手这个时候可以大显身手,帮助企业解决问题。

Industrial robots due to the high degree of flexibility and accuracy in paint dust flying all over the sky painting workshop, the workshop is not coherent two processes, finished product stacking, single processing on the parts casting fields can display skills to the full. For example, in the machining parts on the rear end of the blanking process, loading and unloading manipulator can completely replace the manual operation, not only fast, and high stability, especially in this harsh environment, companies are generally difficult to recruit workers, and the manipulator of this time can help enterprises to display skills to the full. To solve the problem.

深圳市创盈时代科技有限公司是一家专注于注塑机械手,上下料机械手,冲压机械手,工业机器人,非标自动化设备的研发生产和销售于一体的国家高新技术厂家。